Spinner Hanger Shot Blasting Machine (Surface Preparation, Deburring and Descaling, Surface Finishing)

View Seller InfoTechno Bright Industries ✅

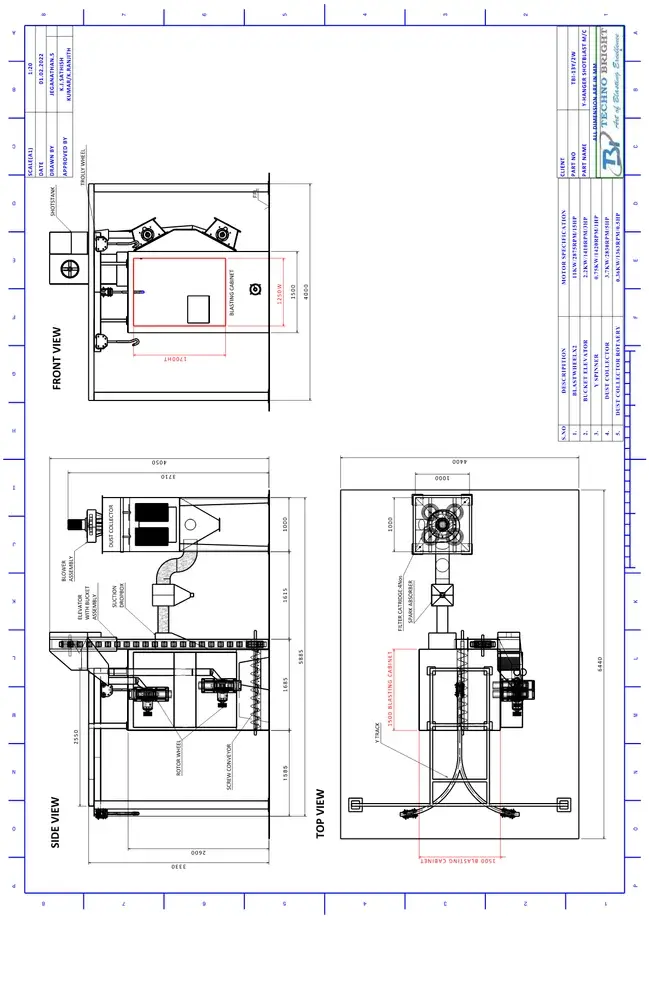

The machine consists of a main blast cabinet, generally as shown on drawing upon which are mounted two standard belt driven wheels positioned as to give the blast best possible coverage of the specified work envelope. The blast cabinet is fully lined replaceable manganese cast liners of size 12” x 12” x 6mm thick for protection of cabinet against rebounding abrasive.

Spent abrasive falls after the blasting operation striking the work pieces, through perforated floor plates into hopper beneath the floor plates from which by screw conveyor it is conveyed to the boot of the belt and bucket elevator. After being elevated, all materials are fed into separator unit, and rotary sieves where oversized and fines are removed by way of the air washing and sieving, prior to the re-circulation of the clean abrasive back to the wheel unit under automatic valve control.

?unique=19918b8)

?unique=19918b8)