Foundry IoT Implementation, Foundry Digitization, IoT Hardware for Foundry

View Seller InfoDyna4Cast Technologies Pvt. Ltd. ✅

ACCOUNTABILITY, TRACEABILITY, and TRANSPARENCY are the three major root causes bringing the same set of problems in core industries like foundries. Getting data from the physical shopfloor is the only solution that can solve these issues but expertise in bringing all the machines, equipment, and process-related signals from various manufacturing units under a single roof is a tedious task that is the solution we are here to provide, one rigid platform to connect the floor level monitoring.

Country: India

For More Information, Download the Brochure

Foundry

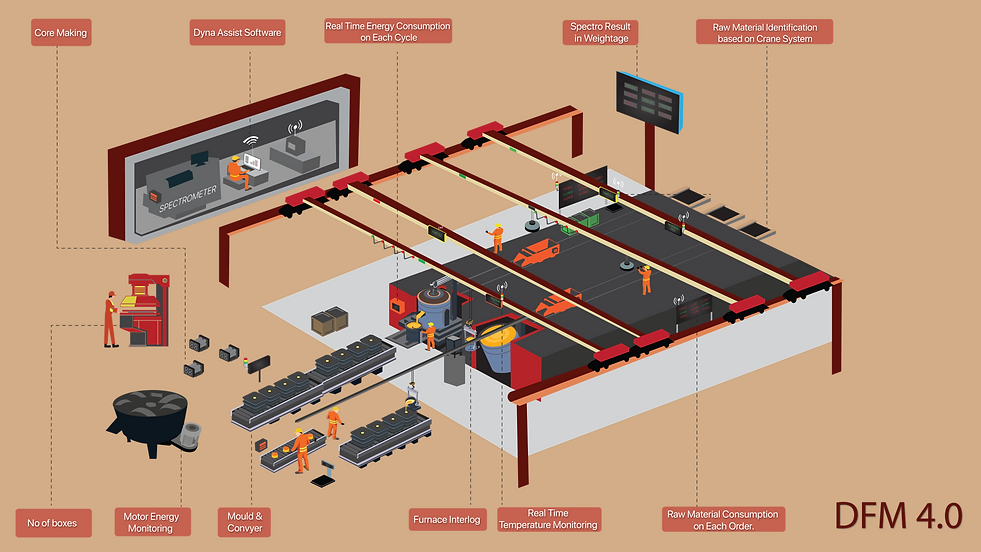

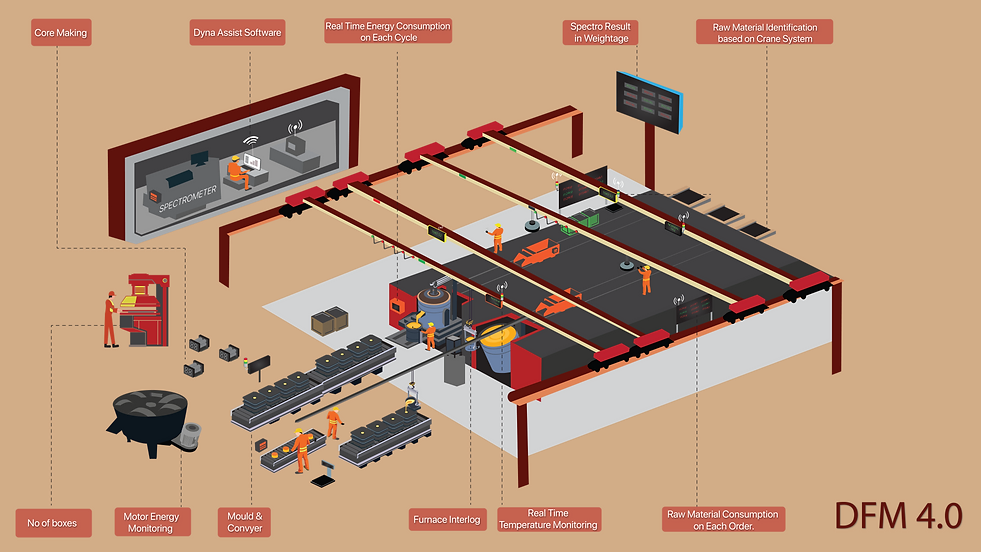

Foundries are the leading industrial parts providers for any type of casting produced which are required for a variety of industries. DFM 4.0 is designed to manage the process of daily requirements of core, mold, furnace and charge preparation, fettling, machining, etc.

- Planning and scheduling of core and mold as per customer ID.

- Furnace planning – scheduling including raw material consumption.

- Furnace optimization- Furnace efficiency, Utilization, charge preparation.

- Energy consumption and CBM on furnace critical parts.

- Real-time monitoring and tracking consumption of Raw material.

- Raw material shortage alert based on customer ID.

- Raw material grade and availability.

- Molding cost and its profitability tracking.

- Core making and pattern management.

- Track additional costs on a single platform.

- Overall cycle time optimization.

- Quality management via integration approaches such as Spectro integration weighing scale integration.

- 24 x7 Online casting Traceability.

- Real-time monitoring and control of all foundry process data.

- Planning as per bottleneck and capacity (MAN, MACHINE, MATERIAL).

Your Dynamic Snippet will be displayed here...

This message is displayed because youy did not provide both a filter and a template to use.