3D Printer - Additive Manufacturing (AM) Machines - Foundry 3D Printing Systems - Extrusion System

View Seller InfoMatrix Moon ✅

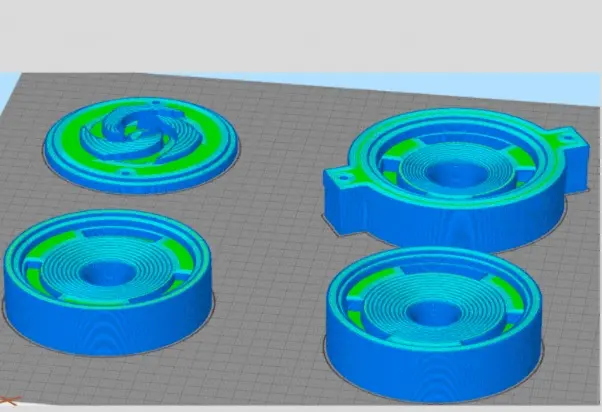

3D Systems' Titan Pellet Extrusion system stands out in the world of 3D printing due to its ability to process a wide range of materials, including industrial-grade thermoplastic pellets. It has several advantages over traditional filament-based extrusion systems, especially for specialized applications like sand casting.

Key Benefits of Titan Pellet Extrusion:

1. Material Flexibility:

- Pellet-based printing allows for a much wider variety of materials compared to filament-based 3D printers. You can use high-performance thermoplastics like ABS, nylon, polycarbonate, and composite materials mixed with glass fibers or carbon fibers. This gives you greater versatility in terms of the final product’s mechanical properties.

2. Cost-Efficiency:

- Pellets are typically more affordable than filament, which makes this system more economical, especially for industrial-scale manufacturing. This can lead to reduced material costs over time, particularly for large parts or high-volume production.

3. High Print Speed:

- The Titan Pellet Extrusion system has a higher throughput compared to traditional filament extrusion systems. This means faster printing, which can be especially advantageous for large parts or rapid prototyping.

4. Larger Build Volumes:

- With the use of pellets, it's easier to achieve a larger extrusion output and, therefore, build larger parts. This is particularly useful for industrial applications, where large components are often required.

5. Improved Mechanical Properties:

- Materials processed through pellet extrusion generally exhibit better mechanical properties such as tensile strength, durability, and heat resistance. Pellets often offer a more consistent feedstock, ensuring reliable output for demanding applications.

Titan Pellet Extrusion in Sand Casting:

Sand casting is a process where a mold is created by packing sand around a pattern, typically made from a material like metal, to form the desired shape. The pattern is then removed, leaving the mold, into which molten metal is poured to form a solid casting.

The Titan Pellet Extrusion system can be used for sand casting in the following ways:

1. Pattern Creation:

- The Titan system can 3D print pattern molds used in sand casting. The printed patterns are often made of materials that can be easily melted or burned out during the casting process. Using a pellet-based extrusion system means faster, larger, and more cost-effective production of these patterns.

2. Improved Design Flexibility:

- With pellet extrusion, you can create complex geometries that might be difficult or costly to achieve using traditional sand-casting patterns. This includes internal cavities, complex shapes, and fine details that would typically require expensive tooling.

3. Increased Strength of the Pattern:

- When creating casting patterns with high-strength thermoplastics or composite materials, the printed patterns can provide better support and resistance to deformation, ensuring more accurate castings, especially for larger, more intricate parts.

4. Rapid Prototyping:

- Titan Pellet Extrusion systems can be used for rapid prototyping of sand-casting patterns. By quickly creating and refining patterns, manufacturers can speed up the testing and iteration phases of casting design before committing to expensive mold tooling.

5. Low-Volume Production:

- Traditional sand casting requires expensive molds that are only cost-effective for high volumes. However, using the Titan Pellet Extrusion system, you can produce low to medium-volume parts for sand casting without the need for costly mold creation. This is ideal for industries that require custom or low-volume casting.

6. Sustainability:

- As 3D printing becomes more widely adopted for sand casting patterns, the amount of waste material is significantly reduced. The precision of the Titan Pellet Extrusion process allows for better material utilization, leading to more sustainable casting practices.

Conclusion:

The Titan Pellet Extrusion system from 3D Systems offers significant advantages over other extrusion-based 3D printers, especially in the context of sand casting. Its ability to print with a wide variety of thermoplastic pellets, produce large parts quickly, and create more robust patterns makes it a valuable tool for both prototyping and low-to-medium-volume casting. The flexibility, cost-effectiveness, and speed of the Titan system give manufacturers the opportunity to improve production efficiency and part quality, making it an ideal solution for industries like automotive, aerospace, and general manufacturing.

Matrix Moon

Matrix Moon is a start-up focused on providing the best technological and industrial training solutions. We, along with our valued partners, are augmenting the adoption of 3D printing technology to further the goal of transforming India into a global manufacturing hub under the Make-in-India initiative. |

%20Machines%20-%C2%A0Foundry%203D%20Printing%20Systems%20-%20Extrusion%20System?unique=4af2d88)

.webp?unique=b854f24)

.webp?unique=b854f24)

.webp?unique=b854f24)

%20Machines%20-%C2%A0Foundry%203D%20Printing%20Systems%20-%20Extrusion%20System?unique=4af2d88)

.webp?unique=b854f24)

.webp?unique=b854f24)

.webp?unique=b854f24)