3D Printed Investment Casting Patterns, Wax Polymer Patterns for Sand and Investment Castings

View Seller InfoStratnel Technologies LLP ✅

Stratnel Technologies LLP is an engineering solutions provider using additive manufacturing technology, based in Bangalore. Stratnel is promoted and managed by seasoned industry veterans with several decades of engineering B2B services. Our holistic approach in coming up with engineering solutions to meet the demanding needs of our customers has helped us in winning and retaining our customers.

Country: India

TRADITIONAL MANUFACTURING

ADDITIVE MANUFACTURING

Applications that we serve include the following:

Prototypes for design validation

Production aids including patterns, fixtures and jigs

Production parts designed with DFAM, meant to be made using an additive manufacturing process

INVESTMENT CASTING

ADDITIVE MANUFACTURING FOR INVESTMENT CASTING

Investment Casting

Investment casting involves pouring molten metal into wax patterns coated with ceramic slurry. The first part of this process is to make moulds into which wax gets injected to make wax patterns. The important part of investment casting is that the wax patterns are single use. During the process of making these parts, the pattern melts away and gets destroyed.

Investment casting or lost wax casting provides certain advantages over sand casting. Investment casting is more expensive than sand casting. But, the process provides thinner sections. It has better dimensional tolerance and finish. This method is better for casting complex, intricate and fine metal objects. It has a lot of adoption in the jewellery industry.

Additive Manufacturing

Additive manufacturing provides several advantages for Investment casting. The biggest advantage is the fact that one can do away with moulds. Additive manufacturing can straight away print patterns with fine details.

The mould making costs can be very high. So Investment Casting can be very expensive at low volumes. 3D printed patterns may cost more than wax patterns. But there is no need for moulds with 3D printing. So at low volumes, additive manufacturing can bring in economies.

Investment Casting Traditional Flow

Pattern Design

Mold Design

Wax Pattern

Mold Trial

Make Mold

Investment Casting

Part Design

Pattern Design

3D Print Design

Investment Casting

Other Advantages of Additive Manufacturing:

No Mold cost

Reduce Lead time

Cast complex parts

Reduce no. of process steps

Increase Yield

Combine multiple parts

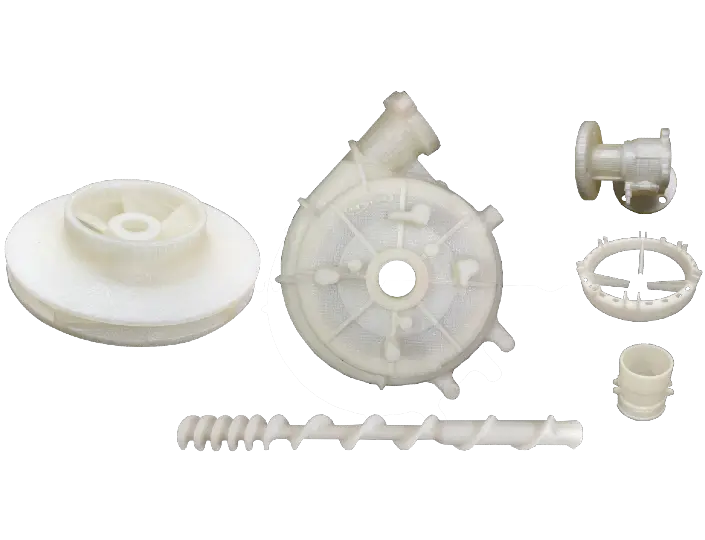

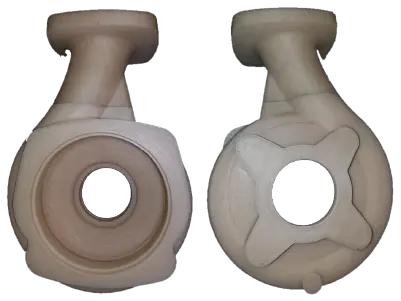

Here are some images of investment casting patterns

printed with Stacker3D S4

Investment Casting Pattern Pump Casting

Impeller Investment Casting Pattern Printed on Stacker S4

SAND CASTING

ADDITIVE MANUFACTURING FOR SAND CASTING

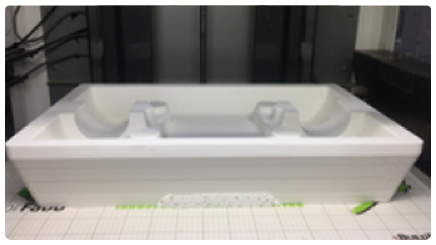

Sand Casting Patterns

Sand Casting patterns printed for our customers

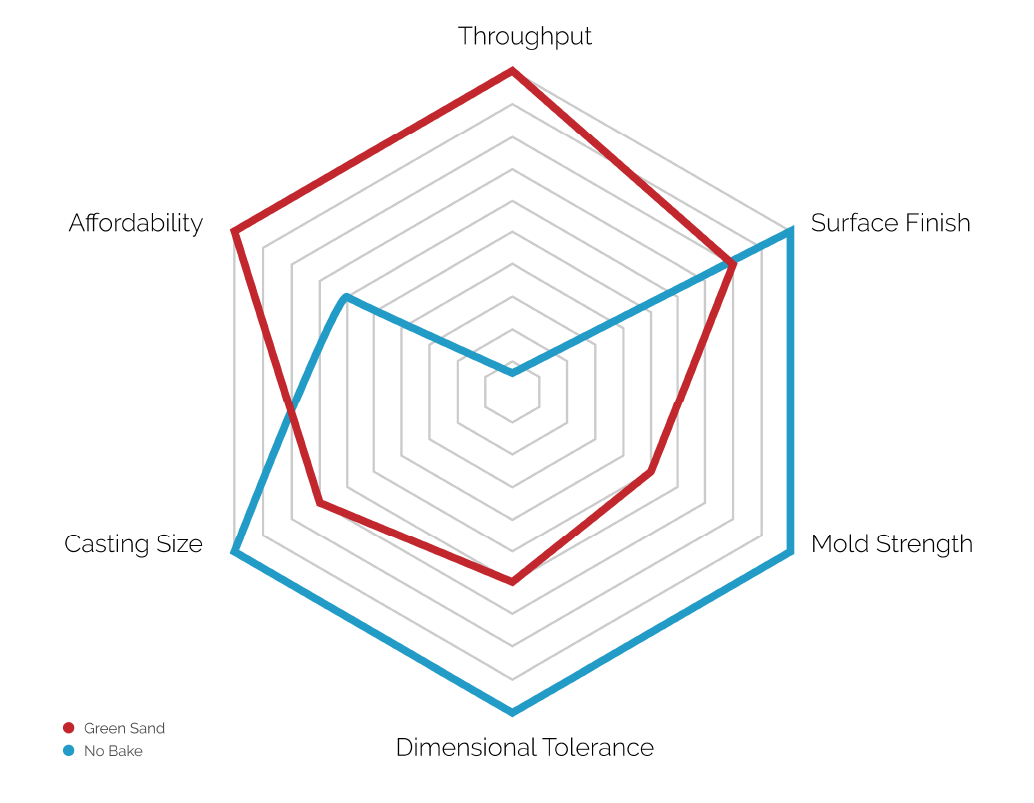

Traditional Sand Casting of Metals in the FOUNDRY INDUSTRY

Sand patterns are a crucial aspect of the foundry industry, used to create cast metal products. Two main types of sand casting are green sand casting and no bake casting. Green sand casting is the most common, utilizing low-cost moulds with refractory properties. This process is more popular than no bake casting, with around 70% of foundries using it. Green sand casting is also automated, with various equipment available for compaction and casting. No bake casting, on the other hand, is versatile and can handle large casting sizes with good dimensional tolerance. Both methods are essential for producing high-quality metal products.

Here is a Comparison table between the green sand and no bake processes.

Metal Casting Process: Green Sand Vs No Bake

Sidestepping the mold making process means it is now faster and cheaper to make products. This gives foundries the following advantages:

- Pattern printing can happen in a day or two instead ofseveral weeks for the mould.

- Mould costs are completely averted.

- Since pattern costs are low, the number of prototypes can be higher.

- Low volume jobs become profitable.

- Customization of existing parts is now possible. So product variations are no longer a problem.

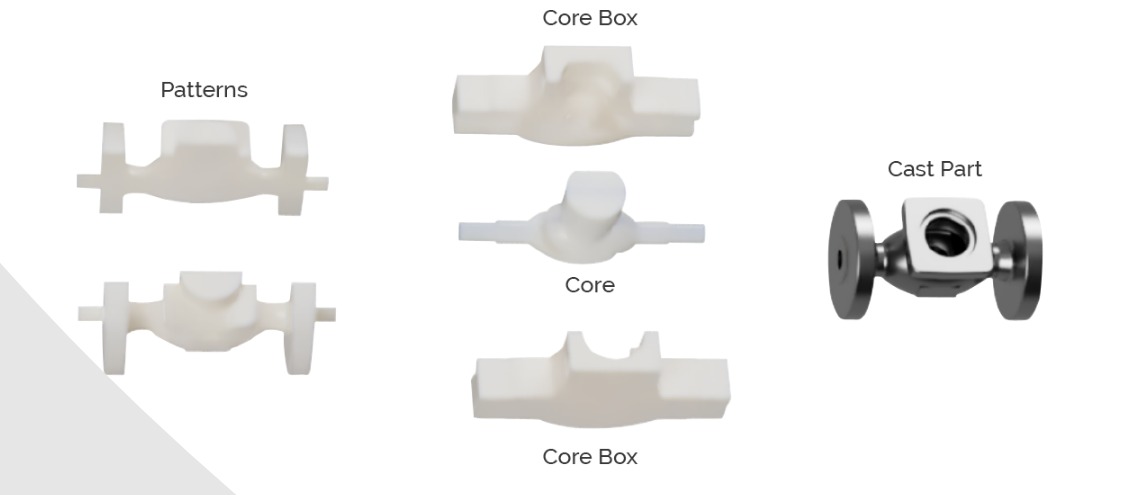

Here is an example of the parts that can be printed for casting a valve:

Get in touch with us

Reach Us: 40/1, Srinivas Enclave, Goshala Road, Garudachar Palya, Mahadevapura, Bangalore 560048.

Contact: +918049501550

Email: stratnel@stratnel.com